|

Page Directory

Introduction

General Notes

Changeovers

Table Saw

Disk Sander

Lathe

Drill Press

Horizontal Bore

More Pics

The Bottom Line

Specifications

Contacts

Multimedia

Other Owners

Site Directory

Home

Tool Reviews

Projects & Plans

Articles

Our Shop

FAQs

Sites I Like to Visit

Build a Kayak

E-Mail Us!

Shopsmith

Shopsmith Mark V

SS Users Group

|

|

I purchased my Shopsmith 510 in 1990 to supplement a 10" Craftsman table saw. I paid $2,000 for the Shopsmith, the 6" x 48" belt sander,

and the Shopsmith Dust Collector. When I purchased the Shopsmith, the Model 510 was new, released in 1985. It offered a larger main table, extension wings with legs, a geared "rack and pinon" mechanism for raising and lowering the table, an improved fence, and a "second" quill bearing to reduce load on the quill. However, I quickly out grew the capacities and design flaws of the Shopsmith. Today, I use it as disk and belt sanding center. Occasionly, I use its drill press function and lathe. The Shopsmith is definitely one of my disappointments as far as woodworking tools go. However, I like having it around for what it does well. I purchased my Shopsmith 510 in 1990 to supplement a 10" Craftsman table saw. I paid $2,000 for the Shopsmith, the 6" x 48" belt sander,

and the Shopsmith Dust Collector. When I purchased the Shopsmith, the Model 510 was new, released in 1985. It offered a larger main table, extension wings with legs, a geared "rack and pinon" mechanism for raising and lowering the table, an improved fence, and a "second" quill bearing to reduce load on the quill. However, I quickly out grew the capacities and design flaws of the Shopsmith. Today, I use it as disk and belt sanding center. Occasionly, I use its drill press function and lathe. The Shopsmith is definitely one of my disappointments as far as woodworking tools go. However, I like having it around for what it does well.

- Power. The Shopsmith is underpowered. It has a very small, non-industrial, 1 HP motor. Shopsmith claims it develops 2 HP. Yes it will, but only at the point of burning up. If the motor drew enough current to develop 2 HP, it would quickly disintegrate. Period.

- Power. It runs on 120VAC and only draws 12-13 amps. You can run this tool, anywhere. I have a friend who made furniture in a single bedroom of his two bedroom apartment using just a Shopsmith. Amazing!

- Varible Speed. The variable speed is nice. No other table saw has it.

- Variable Speed. Everytime you power off the machine, you have to turn the speed dial to slow. Powering on the Shopsmith in any other speed position is not recommended and can lead to premature failure of the unit. This is a pain!

Flash! Flash!..A number of Shopsmith owners have emailed me indicating that I am mistaken in this regard..turning the speed dial to slow before turning off the machine. Necessary or not, the caution label glued onto the headstock indicates that you must turn the speed dial to slow before turning off the machine. Furthermore, here is the "official statement" I recieved on 8/21/2000 from Shopsmith Technical Service:

"Although some folks do turn their unit off at high speed, we DO NOT recommend doing this.

It is a sure way to mess up your speeds, therefore requiring a high speed calibration, as well as your belts and pulley's."

- Five-in-One. It is nice to have "five" machines that fit into the space of a bicycle. It is definitely a "neat" machine for those of you who like machinery in spite of its flaws.

- Five-in-One. Tool changes can be a real pain as described below. Almost every woodworking process is easier on conventional machines.

- Accessories. The accessories do not disappear when not in use. You have to plan and provide shop space to house the bandsaw, belt sander, etc. when not in use.

- Accessories. Tons of accessories, some well designed others are not. The new Universal Lathe Tool Rest is incredible. The lathe-duplicator is reportedly a well designed accessory. The scroll saw is not. I have the belt sander and think it's great.

- Support. Support is incredible, but they definitely lean towards the home shop user, which is fine for 95% of all Shopsmith users. Their web site has lots of projects, tips, etc. Their documentation is very well done. Everything leans towards fun.

- Maintenance. You have to perform periodic preventive maintenance if you want to keep the Shopsmith running smoothly. Occasionaly, you need to pull the headstock cover, oil up the VS Shaft, etc. Not a big deal, but ....

- Mobility. Because of its light weight and excellent casters, you can easily move the Shopsmith around and lock it into place. I have heard of Shopsmith owners transporting the unit to a work site. May not be practical, but certainly is possible.

- Fit and Finish. Generally excellent fit and finish. The unit is a piece of cake to setup / install. Setting the table square to the blade (disk sander) is a piece of cake. I was afraid that the chrome steel tubes would rust. Nope.

- The price of parts and accessories is outrageous! Wait for the sales!

The Shopsmith people will lead you to believe that you can change from one tool setup to another in a matter of seconds.

This is partially true. You can switch from the table saw to the drill press or any other setup in less than a minute. The problem is, they are not counting the "setup" time for any given operation and the fact that you will "lose" the setup when changing from one tool to another. Some setups are not easily changed and repeated. For instance, if you set the drill press to drill a hole at a particular angle and depth, and then find you need the saw....yikes, you have to tear down your drill press setup:

- Return the headstock to the horizontal position.

- Move the headstock to the general area for sawing. Make sure you lock it down.

- Rotate the table for sawing.

- Remove the drill chuck.

- Install the lower saw guard.

- Install the blade.

- Install the upper saw guard.

- Replace your drill table insert with the saw table insert.

- Move the table up, over, and into place. Make sure you lock it down.

- Adjust the saw blade within the saw insert.

- Adjust saw blade height.

- Adjust the fence, etc.

After making your 5 second cut, you've got to go back to the drill press setup......Are any of the steps particularly difficult? NO. But it

gets old real fast. Regardless of what anyone says, switching back and forth from one setup to another is time consuming and is tedious.

- I believe the table saw to be the most important tool in the shop. However, The Shopsmith table

saw leaves lots to be desired.

- Low power. The motor is TINY! It is obviously not an industrial - continuous use type of motor.

- Small table does not provide adequate space in front of the blade or at the rear.

- No way to fix a measuring tape for convenient and consistent rip cuts.

- The blade arbor is fixed. This is not a tilting-arbor saw. Rather, the table is adjusted for

height and bevel. This prevents you from mitering long pieces and beveling wide pieces. Since gravity is working

against you and the height adjustment threads are coarse, adjusting height to an exact position can

be frustrating. I can adjust the height to within several thousandths of an inch (for box joints for instance), but it is

a pain. Since the table adjusts vertically and for angles, outfeed tables are difficult to attach

and use with the Shopsmith. If ever a machine required an outfeed table it is the Shopsmith, but no

machine makes it more difficult to attach and use one.

- The entire table assembly deflects under heavy pressure. However, for small work the table is fine.

- The table is a bit high for me, even at 6'2". I have all of my stationary tools (table saws, shapers) set at 36", which is too high for some. The Shopsmith is higher yet at 40-42".

- I have come to dislike aluminum tables. They can mar the work, they do not provide the easy glide surface of cast iron, etc.

- The miter gauge is cheap, but its miter bar can be tightened to lock in the the miter slot. This is handy as a fence for drilling operations.

- The variable speed has come in handy when cutting / molding particular difficult materials.

- Works pretty well as a tile cutter.

- The extension tables, if you can adjust them to the correct height, do provide good left/right support. However, they are very shallow.

- The blade guard and splitter are pretty good.

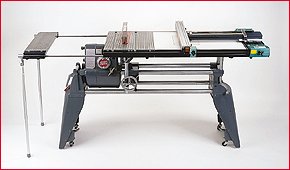

Jointech recently introduced their saw train and router system for the Shopsmith 510. This might breathe new life into the Shopsmith Mark V. The price is a bit high ($1100.00) but it looks really trick. Of course there is still a lot of fiddling around to do to raise blades, tilt the table, etc. To cut a bevel (tilt the table) you have to disconnect the Jointech assembly from the main table. To raise/lower the table, you have to raise/lower the main table using the Shopsmith mechanism and then raise/lower the Jointech assembly using their "makeshift" jackscrew until the two units are level. To perform a tool changeover, you have to pretty much remove the entire Jointech assembly and find a place in the shop to store it, albeit temporarily. Also, you cannot use the standard Shopsmith fence with the drill press or any other operation. You can check out the Jointech Shopsmith Saw Train at Shopsmith Saw Train. Jointech recently introduced their saw train and router system for the Shopsmith 510. This might breathe new life into the Shopsmith Mark V. The price is a bit high ($1100.00) but it looks really trick. Of course there is still a lot of fiddling around to do to raise blades, tilt the table, etc. To cut a bevel (tilt the table) you have to disconnect the Jointech assembly from the main table. To raise/lower the table, you have to raise/lower the main table using the Shopsmith mechanism and then raise/lower the Jointech assembly using their "makeshift" jackscrew until the two units are level. To perform a tool changeover, you have to pretty much remove the entire Jointech assembly and find a place in the shop to store it, albeit temporarily. Also, you cannot use the standard Shopsmith fence with the drill press or any other operation. You can check out the Jointech Shopsmith Saw Train at Shopsmith Saw Train.

- The small tables for the table saw are actually very large, relatively speaking, for the disk sander. I often use the

disk sander with large panels to round a corner, or so forth. Most disk sanders are equipped with tiny tables that

are worthless for the size of workpieces I deal with.

- The fence, uncommon on most disk sanders, comes in handy.

- A 12" sander seems much larger than 10" sanders.

- Very easy to change from the table saw to the disk sander.

- Dust collection works moderately well.

- The 1 HP motor provides plenty of power for the Disk Sander.

My biggest complaint about the lathe is the tool rest. Instead of sliding in and out, it pivots. Trying to get it set just right is a royal pain. However, the new Universal Tool Rest (shown to the below-right) is fantastic. First of all it weighs in at over 30 pounds. It is solid cast iron and does not flex in the least bit. Its tool rest arm is the heaviest, strongest, and longest arm I have ever seen. It is a bit pricey, but I believe this new accessory is a must for anyone doing "serious" turning on the Shopsmith. My biggest complaint about the lathe is the tool rest. Instead of sliding in and out, it pivots. Trying to get it set just right is a royal pain. However, the new Universal Tool Rest (shown to the below-right) is fantastic. First of all it weighs in at over 30 pounds. It is solid cast iron and does not flex in the least bit. Its tool rest arm is the heaviest, strongest, and longest arm I have ever seen. It is a bit pricey, but I believe this new accessory is a must for anyone doing "serious" turning on the Shopsmith.

- The variable speed is nice, but the slowest speed is too fast for some roughing operations.

- The stock tool rest flexes. Get the new Universal Tool Rest.

- The copy - duplicator seems to work pretty well. I don't have one, but Norm used it for a number of projects.

- The headstock uses a 5/8 plain shaft. The better accessories are designed for threaded shafts.

- Centers are too low for my liking. I like the turning center to be near chest high. The Shopsmith center's are about belt high at about 39".

- The light weight of the Shopsmith would cause problems if you turned large or off balance work.

- The 1 HP motor provides plenty of power for the lathe, though I cannot say I have ever taxed it.

- The tailstock is very light and I prefer a mobile tailstock. Since the drive spindle travels, a mobile tailstock is not absolutely necessary, but...

|

- I really like the drill press function, with the exception of the change over hassle described above.

- The 1 HP motor is exceptional for a drill press.

- Having the large table, adjustable for height and angle, the headstock adustable for height, really works well. Allows you to drill pocket holes, round work, sequential drilling, and so forth.

- The table saw fence works great as a drill press fence. I attach a Mark Duginkse DP aluminum fence with two stops

for exacting work, such as for drilling drawer fronts for drawer pulls and the like. Works really well.

- The slowest speed is too fast for large cutters, such as fly-cutters.

- The quill stop works very well and is super easy to set. Faster and easier than my floor drill press.

- The chuck is very high quality. Much better than my floor drill press.

- Does not accept Morse taper chucks and accessories.

- Shopsmith does not recommend that you use mortising attachments. The quill design and bearings do not support the

force necessary to chisel mortises. Using such attachements will almost certainly lead to premature failure.

- Standard quill handle is okay. I suggest buying the accessory handle that provides three levers rather than the

standard one.

It works as advertised. I have only used the feature a couple of times.

It works as advertised. I have only used the feature a couple of times.

More Shopsmith Pictures

Click here to view more pictures of our Shopsmith and its tool shelf.

After tiring of the endless setups and tear downs and increased disappointment in the inadequate table saw and lathe components, I tried selling my Shopsmith a few years after purchasing it. I received one call in six months of Trading Times advertisments. I decided to keep it for sanding and lathe operations and works very well for those operations.

Consequently, I strongly recommend that woodworkers consider buying conventional tools rather than a Shopsmith.

However, if the Shopsmith bug is too great, buy a used one. Of course, if you have had the opportunity to use a Shopsmith and know it's for you, go ahead and buy it new. When all is said and done, the Shopsmith is one of my favorite tools and one of my least favorite tools. If I could have it to do over again, I would not buy a new one, but I would definitely buy a used one. To make my matters worse, I ended up paying for my Shopsmith a "second time" as part of a divorce settlement. Talk about adding insult to injury!

By the way, I should add...I have seen some pretty incredible pieces of furniture and cabinetry machined using only a Shopsmith. For instance, check out Tom Almy's Site. I have a neighbor who built a High-Boy Chest of Drawers with arched moldings, etc, using the Shopsmith. Another friend used to build high-end, commissioned furniture using a Shopsmith until he could afford better equipment. He actually worked out of one room of a two room apartment! Think about it, tens of thousands of craftsman have built and continue to build countless pieces of furniture by hand.

Click here for Shopsmith Mark V Specifications.

Shopsmith documentation and support is really second to none. Here is a table of contacts:

| US & Canada |

| 1-800-543-7586 |

Orders & MARK V Accessory Catalog Information |

| 1-800-762-7555 |

Customer Service & Technical Support |

| |

| International |

1-937-898-6070

Ext. 375 |

Orders & MARK V Accessory Catalog Information |

1-937-898-6070

Ext. 376 |

Customer Service & Technical Support |

| |

Order by Fax

1-800-722-3965

1-937-890-5197 |

Order by Mail

Shopsmith, Inc.

Attn: Order Department

6530 Poe Ave.

Dayton, OH 45414-2591 |

|

I have been using my Shopsmith for about 12 years now and find it to be an extremely versatile tool. Changes from one tool to another are not nearly as bad as many people claim and they can be minimized by planning your work to eliminate many of them. For a while I was into making pems and pencils and found the horizontal boring a blessing with the aid of a small jig I made to hold the stock.

I do a lot of bowl turning using rejects from the fireplace wood, rotten stumps, root balls etc. I fortunately acquired one of the speed reducers which makes off balance work a snap.

I have never lowered my speed before turning it off and see no reason to do so. however I have worn out several switches over the years.

Can't think of any major problems with it unless you compare it to a high priced free standing tool.

For my money I think it is great. Of course I am not the kind of guy that will go out and buy a high power SUV to drive 4 or 5 miles in the city to get to work. For a homecraftsman or hobby shop it can't be beat.

I used to own an older model 10ER Shopsmith.I paid $100 for it and sold it about 10 years later for $100.

Sure it was a pain to set up the machine from one operation to another, but to replace that machine with individual tools,

would cost a small fortune. I did some pretty serious work with it. I still have the 12" sanding disc, which I have mounted

on a spare motor and a shop built table. Overall, it's a good tool for the weekend warrior, but not worth the present day

price tag. If I was to buy one today, I would only shop for a used one. I think the best feature of this machine was the

horizontal boring feature.

I used to own a Shopsmith. While it works good at some things here are my complaints.

- Tool change. Life is too short to keep going from a drill press to a table saw.

- The table saw table was much too small. I owned the largest model with all of the table extentions and it was still too darn small.

- Dado work on the saw is almost impossible with large pieces of ply wood. Since the table is raised and lowerd to adjust cutting depth is hard to create an accurate cut.

- The Drill press is just to shallow for wood working.

- Tilting the table to make a cut is a nasty ......

Now all that said. I makes a nice variable speed lathe. Ok lets see $1600 for a VS lathe. I paid $250 for a VS lathe from HF.

Even if you dont have the space I think you can do better with smaller bench top tools.

A Powermatic 66 it ain't. I'd probably put it about equal to a basic contractor's saw but better than a benchtop.

Changeover takes a little time, but is only a minor nuisance rather than a major one. When I moved from a house with shop

room to sharing a garage, I chose to get rid of my BT3000. Would I like stand along tools? Of course when I can afford to

build a separate shop. Until then, I'll happily use my Shopsmith.

I've owned and used a Shopsmith Mark 5 since 1953. Even with triple the space I originally had and with a table saw now,

I'm still cramped for room. No tilt-table saw is a good table saw, but I've done some good work with mine, including

compound cuts for shadow box frames and long bevels on paneling boards. It's a good disk sander and with the new attachment,

a fine spindle sander. It's not only a passable drill press, but how else can a home user bore horizontally? Lathe work scares

me, so I use it very litte and would buy a heavier unit if I liked the work. Bottom line: if you're cramped for space, a

Shopsmith is a quality product that can do some things superbly and some well enough to get by without freestanding

one-purpose tools.

I have a Mark V 500 w/ bandsaw, belt sander and jointer that I've used frequently since I got it new in 1983. I bought it

because I lacked space for separate tools yet I still wanted to woodwork. I've found it to be a quality machine and well

worth what it cost me. Because of it, I've been able to engage in my favorite pastime for a number of years. I've posted in

this forum and others several times about my experience with it which has been positive in every way. I've made some

quality furniture with it and I've regularly cut 8/4 Oak with it (no, I don't do it everyday all day long).

I take exception to statements that top quality woodworking and cabinetry can't be produced using a Shopsmith. That just

isn't so and that isn't based solely on my experience. There are a number of woodworkers using Shopsmith equipment who are

far more skilled than I producing absolutely beautiful work. Once you get used to "thinking" in Shopsmith terms,

changeovers are quick and easy.

Clearly, such a concept was never intended for production shops, but to say its a piece of junk or a toy just isn't

accurate. I've never even seen a Mark II, but the Mark V's are all well made machines.

That all said, I will be filling my new shop with stand alone machines. I will keep my Mark V, though. It will come in

handy as a secondary machine and there are some operations that I'm just used to using it for (i.e. drilling for Euro

hinges or into round stock or horizontally). I think it comes down to this for the woodworking hobbyist: If you are short

on space, go with the Shopsmith. If you're not, go with the stand alone machines.

With all due respect to the others who've posted in response to your question, I would advise you to check out the

Shopsmith User's Group list. Correspond with some of the members there and ask them what they think. In particular,

Tom Almy whom Jack references in his very thorough and excellent review of the 510.

Lest someone come back with the idea that us SS owners wouldn't complain about something we already own, that same

argument can be used in regard to almost anything, PM66's and Inca's included.

And speaking of Inca, when I bought my Mark V, the then current Inca base model saw didn't have a table that was much

bigger than the Mark V. The SS configures as a tilting table saw rather than a tilting arbor.

Pardon me if I appear defensive, but I just think you're not getting both sides of this never ending "argument". If you're

short on space, a SS may be the way to go for you. If not, you may want to consider stand alone machines. But don't dismiss

it out of hand.

In response to a bulletin board post...

But the current model is far superior to that model. No, it's not the end-all of tools, but when you are limited on space,

or funds, it can become the only answer that works. However, I would not buy one new. I *do* have one, which I picked up a

year ago used. I bought it intending to supplement with a cabinet saw (still in the works...) since I don't have space for

a full shop full of tools. One can be had used for a reasonable amount of money.

As for the bandsaw. Yes, it is over priced. *But* $150? Nahh, it is worth more than that. Heck, it's even worth more than

the craftsman rejects you compare it to. Is it a little small? Maybe, depends on what you are cutting. Can it be configured

to be dead-on accurate? you betcha! Oh, and does it have easy to use and really reliable mechanisms that in many ways beat

out much larger saws?

Yeah, it has that too.

Oh, if it matters, it's also made in the good ol' USA...

I have owned a Shopsmith for 9 years and it has performed as expected. The ONLY reason I purchased this tool was that I did

not have the space for single tools to work on my HOBBY. I bought the 510 with a band saw, jointer, and dust collector.

As my needs and situation changed, I started buying single tools of better quality. My first single tool was a Jet 10"

cabinet saw. This was because the table saw on the Shopsmith is the weakest part of the tool and is very limited on the

type and quality of work you can do with this tool. It really depends on what kind of work your going to do and how much

space you have or don't have whether or not you should buy this tool.

This tool has served me well but is not suited for TOP quality cabinet and furniture making. Just my $.02 worth.

Cincinnati Dave

I purchased my Shopsmith new in 1989 and have used it ever since to build a house full of furniture for others and myself. The thing is built like a tank. I am still using the same belt that it came with. I have been on this d-group for over 3 years and I never see a post like " Problem with my Shopsmith". I rip 2 inch Cherry all the time with no problem with power. I guess if I were use to a 5hp. 240V. powermatic 66 table saw it would seem underpowered. I taught myself woodworking on the Shopsmith and learned to cut all my wood, then change over and drill my holes etc…. Change over are quick but could see if a person was use to stand-alone tools would be bothered by it. The new fence they offer on the 510 is great. Another thing to think about when Shopsmith upgrades its tools they always make it so you can upgrade your older tool to the new model. Now I

will tell you I am in the process of buying standalone tools because after 15 years I know woodworking will be my lifelong hobby and I have the room (5 car garage) BUT… I purchased a drill press because I am doing a little metalworking and don't want to get oil on my Shopsmith when I drill. I don't see how people do woodworking on a regular drill press. They are made for metalworking not woodworking. The shopsmith variable speed and tilting tables are great. I purchased the Jet 6" jointer

because of the longer tables than the shopsmith 4" but I miss the Variable speed on my jointer. If I had to do over I would have just keep using my Shopsmith and spent the $500 on something else. (Not saying the Jet is no good, it is) I am also getting the Jet 10" cabinet saw but I have been riding the fence for 2 years now and could easily be talked out of it because

my Shopsmith WILL do everything I want it to. I know I will miss the variable speed on the table saw also. I'm 32, single and got money to burn :-). In short if you have the room and know woodworking will be your hobby for a long time, get stand-alone tools if not go for the Shopsmith. PS. My Shopsmith band saw will not be going anywhere. It is great!

I grew up learning woodworking on my Dad's Mark II. Four year's ago I purchased the Mark V. I

would have loved to get the Delta 52" and other stand-alone's but I just did not have the room.

I enjoy the flexibility the Mark V offers me in one complete package. You hear alot about "...But

the tool changeovers are such a pain." I really don't mind the changeovers. when I'm building

something, it's not like I'm in a rush to get a project done. My Honey-Do List is never ending.

I'm not all that crazy with the table saw part of the Mark V however, like anything else in life,

everything has it's quirks. I've just learned to get around that shortcoming, (Get's out of

alignment) by checking both the table and table to blade alignment after every two or three

changeovers. You see other types of Combination tools much like the Shopsmith on the market,

(Total Shop, Smithy (sp), all taking shots at Shopsmith on how their heavier, better, etc. I

grew up using a Shopsmith more than 30+ years ago and if I still had my Dad's Mark II, I could

get parts for it today! I bought my Mark V four years ago at a Home Show. If you buy new, that's

the place to get one. Not only would the price be lower, they wanted to throw in their dust

collector. I told them I would prefer the Jointer which I got without any problems. As mentioned

by other individuals, I love the casters. Would be lost without them. The Mark V is not for

everyone, but for me it does everything I need it to do. It does it well IF you take your time to

do it right and I know 30 years from now mine will still be running.

Bryan Corley shared these pictures of this great tool cabinet he designed and built for his Shopsmith. Note how it "hangs" from the support tubes. Ingenious! Nice Job Bryan!

To the author of the Shopsmith review:

Dear Sir:

I can relate 30 years of experience with a Shopsmith Mark V which I purchased new in 1974 together with their belt sander, jigsaw and bandsaw with separate stand and 3/4 Hp motor. I also bought a used 4" Delta jointer (because I could not locate a used 6" one or afford a new one at that time). That Shopsmith machine enabled me without any prior woodworking experience (and only books and magazines to teach myself) to build a wall-to-wall and floor-to-ceiling bookcases on cabinets from solid cherry and cherry hardwood paneling, and another set from solid oak, and several pieces of solid walnut and cherry furniture including coffee tables, end tables and other built-ins. The quality of the finished pieces was good enough that no one thought them "homemade" [sprayed and rubbed lacquer finish on most], other than those who knew enough about the absence of solid black walnut furniture. In fact, several people asked me if I would consider making items for them for payment. I made two hexagonal lamp tables having over 125 cut wood parts each including an inlaid burlwood top, all sides and doors of frame and panel construction, and all joints between the segments of the top, sides and base members fitted with hardwood plywood splines. A router with an ogee bit that I modified to remove the bottom shaft extension together with a radius-following edge guide was used to create the raised panels. Later I added a radial arm saw and a Belsaw 12" planer, and even later sold the Belsaw and bought the 10" Inca combination planer/jointer.

My overall experience with the Shopsmith organization has been excellent. When the manufacturer later introduced the double bearing on the spindle, they retrofitted mine at no charge, and plated the spindle sleeve to reduce radial play in the spindle-to-housing. They also replaced the original table which was not flat. The A.O. Smith motor in my Shopsmith [rated 1 1/8 Hp on its tag] has stood up to what I consider to be heavy duty use for a homeowner hobbyist - including ripping 600 BFt of 5/4 rough sawn red oak of 10 - 15 inches width into 2 1/2, 3, 4, and 5 1/2 inches widths to convert it into T+G flooring on the Belsaw. I was able to do that entire lot of oak with one Shopsmith OEM steel combination blade that had just been resharpened and reset!

Like you, I plan on keeping my Shopsmith for use as a drill press and horizontal boring machine, sanding center and lathe, although occasionally it also still gets use as a saw. As a sanding center I mount the 12 disk sander, the belt sander and attach a 3" drum sander to the shaft of the belt sander. Most other manufacturers would charge as much as the Shopsmith cost for that type of sanding station alone. And they still would not have the Shopsmith's ability to thrust the spinning disk into the work, e.g. to precisely trim sand mitred pieces. I have found the disk sander function coupled with the locked mitre gauge very useful in cleaning up the mitre joints of pieces of solid mahogany and oak door and window trim that I recently removed and reinstalled in my house. The Shopsmith features made is simple to remove any burrs, old finish or glue and true up the faces to be joined as their angles without noticeably shortening them so they could be reinstalled in almost exactly their original positions.

As a horizontal boring machine, e.g. for doweling instead of biscuits, the Shopsmith works very well and is unlimited in length and width as they claim. Due to its extensible spindle, it is also very handy for boring a center hold in lamp spindles. A simple, long spoon bit mounted in the tail stock can work wonders.

As a lathe, besides the deficiencies you mentioned, there is the risk of vibration, due to relatively low mass of the Shopsmith, and lack of rigidity of its frame and components. This is particularly apparent when turning larger pieces mounted only in the headstock or long pieces between centers, but careful technique and sharp tools will get the job done and reduce those vibrations. A homemade backup steady rest can also help greatly.

You identified and described very well most of the shorcomings of a Shopsmith. It definitely does not have the power needed to rip a steady diet of 8/4 oak {although I have!] and is even worse when asked to rip dried 2x4 of southern yellow pine. My personal experience proved that a determined amateur craftsman can do many tasks with it rather well. But the penalty for its shortcomings is a lot of setup time which includes arranging extra outrigger support stands for many operations such as cutting sheets of plywood, ripping or crosscutting long boards and such. The user has to work extra hard, and check the setup very carefully. Due to the relative lack of stiffness of many of the Shopsmith members, the built in indicators, e.g. of angle cannot be relied upon and thus more test cuts and fussing with the setup are often needed. But for light, small pieces, it is very handy and the time to change setups has usually not been a burden. If the Shopsmith were made with much heavier parts and to higher standards and tolerances, it would be capable of much more, but its cost would also be much more.

After I experienced the difference in performance that quality can make through use of my Incra palner/jointer, I decided that I wanted a better table saw, and something to more safely cut plywood sheets. Toward that goal I am buying the Festool saw and Multifunction Table which I am very impressed with after reading your and other reviews. But the Shopsmith will remain for a while as I don't have floor space for separate dedicated tools.

I would also like to comment in reply to your comments about aluminum work contact surfaces for woodworking tools. You are correct regarding the Shopsmith tables. But if you keep them waxed they are not much of a problem when workin with unfinished wood that you are going to finish sand anyway. If you have any experience with the Inca 510 planer/jointer you know that its tables are also made of aluminum, but they are anodized and coated with a hard PTFE (Teflon(tm)) material that is quite durable and does not cause smears or stains on the work pieces. Despite the relatively light weight of the Inca unit, it performs very well and with very little vibration. Its supplied dust collection hood when coupled to a shop vacuum or better yet to a 3/4 Hp or larger dust collector through a 4" hose captures nearly all of the shavings. It, too, is a keeper.

Keep up the excellent tool review work. Yours are among the most comprehensive, best written and thus, most helpful ones, I have found. Thank you !!

David M. Ronyak

I had a shop full of conventional tools, sold my house and moved to a duplex. After a few months and the shopful of tools in storage I began to have withdrawal symptoms. I bought a 510 and used it in my half of a 2 car garage, planning to sell it after I bought another house and built a shop. Well it is five years later, I bought a house, built a shop, got the tools all set-up and believe it or not I still have the Shopsmith. I love it. It won't do all my 3hp cabinet saw will do, and is less convenient than some of the other tools but I will not be without it. I use it on nearly every project and it serves me very well. I may someday have to get rid of the "other tools" but the Shopsmith is here to stay.

Robert Goodknight

Was this article helpful? Do you have any questions? E-Mail Us! We would love to hear from you!

|