Several years ago someone asked me to list my favorite tools, the tools I use the most. Here it is. The list has changed since I originally responded. Also, I have added a few tools that do not functioned like I believed they would.

Powermatic Model 66 Table Saw

When I started building cabinets and larger pieces of furniture, I decided the contractor's saw had to go. I wanted the "best" saw I could afford. This was it. When I purchased this saw in 1991, the choices were basically Powermatic, Delta, and General. Today, I could be persuaded to buy a slightly lesser saw. In fact, we recently purchased a Grizzly 1023S and have found it to be extremely accurate and quite frankly a joy to use. But still, the Powermatic is my absolute favorite tool I own. I love the Biesemeyer fence, the power, the smooth feel of the mechanics, the left-tilt arbor, and so on.

When I started building cabinets and larger pieces of furniture, I decided the contractor's saw had to go. I wanted the "best" saw I could afford. This was it. When I purchased this saw in 1991, the choices were basically Powermatic, Delta, and General. Today, I could be persuaded to buy a slightly lesser saw. In fact, we recently purchased a Grizzly 1023S and have found it to be extremely accurate and quite frankly a joy to use. But still, the Powermatic is my absolute favorite tool I own. I love the Biesemeyer fence, the power, the smooth feel of the mechanics, the left-tilt arbor, and so on.

|

Kreg Pocket Hole Jig

Next to the table saws, this is one of my most used and most indispensible tools. I have drilled thousands of pocket holes with this jig and am amazed just how quickly and easily one can assemble cabinets using the Kreg pocket hole jig and the Sommerfeld cabinet making process/system. We'll soon see how the new Marc Sommerfeld/CMT pocket hole jig performs.

Next to the table saws, this is one of my most used and most indispensible tools. I have drilled thousands of pocket holes with this jig and am amazed just how quickly and easily one can assemble cabinets using the Kreg pocket hole jig and the Sommerfeld cabinet making process/system. We'll soon see how the new Marc Sommerfeld/CMT pocket hole jig performs.

|

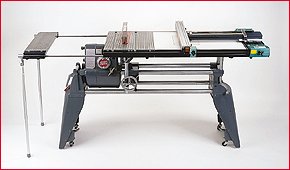

Dubby Cutoff Fixture

I do 90% of my crosscuts with this fixture. Sure you can build your own. I have built several crosscut sleds. The Dubby fixture just seems to work better than mine. I love it. I like the sled carrying the material, I like the the zero-edge aspect of the sled, I like the long robust fence, the repeatable angles, and Jerry Cole is an absolute delight! I have wasted a considerable amount of money on miter gauges that don't see the light of day. I do 90% of my crosscuts with this fixture. Sure you can build your own. I have built several crosscut sleds. The Dubby fixture just seems to work better than mine. I love it. I like the sled carrying the material, I like the the zero-edge aspect of the sled, I like the long robust fence, the repeatable angles, and Jerry Cole is an absolute delight! I have wasted a considerable amount of money on miter gauges that don't see the light of day.

|

Bessy K-Body Clamps

The absolute best clamp I have ever used. They are worth the price--believe me! American clamp companies should rethink their wares*, they just don't compare. This clamp squares up a workpiece rather than skewing it like the American varieties. Non-marring jaws, straight as an arrow bars, and easily moveable jaws all add up to the best clamp for anywhere near the price. (*Interesting, some two years after I made this statement, indeed Jorgensen has released their "cabinet maker" clamps, and they indeed, rethought their wares! It is a good clamp and may very well be the equal to the Bessy K-Body.) The absolute best clamp I have ever used. They are worth the price--believe me! American clamp companies should rethink their wares*, they just don't compare. This clamp squares up a workpiece rather than skewing it like the American varieties. Non-marring jaws, straight as an arrow bars, and easily moveable jaws all add up to the best clamp for anywhere near the price. (*Interesting, some two years after I made this statement, indeed Jorgensen has released their "cabinet maker" clamps, and they indeed, rethought their wares! It is a good clamp and may very well be the equal to the Bessy K-Body.)

|

Bessy Tradesman Clamps

Virtually every could use a bunch of these inexpensive, tough, non-marring clamps. They are many time stronger than the Jorgensen 3700 series F clamps. Virtually every could use a bunch of these inexpensive, tough, non-marring clamps. They are many time stronger than the Jorgensen 3700 series F clamps.

|

Porter-Cable 690 Router

I have several PC 690 routers. I like their toughness, their ease of height adjustment, their feel, and so on. I read awhile back where someone said that after using the Bosch 1617 EVS router, the PC 690 felt like a toy. I have logged lots of hours on both, and I prefer the PC 690. I do like the Bosch soft start, lever release, and fine height adjustment, but in use the Bosch feels top heavy (to me), I have difficulty removing the templates (Clic template system) without hammering on the release lever, and I don't like the base height adjustment system. I guess I prefer simpler mechanisms. I have several PC 690 routers. I like their toughness, their ease of height adjustment, their feel, and so on. I read awhile back where someone said that after using the Bosch 1617 EVS router, the PC 690 felt like a toy. I have logged lots of hours on both, and I prefer the PC 690. I do like the Bosch soft start, lever release, and fine height adjustment, but in use the Bosch feels top heavy (to me), I have difficulty removing the templates (Clic template system) without hammering on the release lever, and I don't like the base height adjustment system. I guess I prefer simpler mechanisms.

|

Porter-Cable 7518 Router

The PC 7518 is the best router I have ever used. I like its heft and feel. The handles are incredible--meaning they feel right and provide lots of control. Unfortunately, I put in a router table and have not removed it since for hand held routing. Shame. It's not a perfecttool. For instance, its speed fluctuates a bit. However, for router table applications, I doubt you'll find a better, stronger router for the price. By the way, I replaced a Makita M12V with this router. The M12V is now relegated to hand held work. (By the way, the Makita M12V makes a fine router-table router if you remove the springs, add the $80 Router Raizer, and use the bent arm wrench from Sommerfeld. I probably would have been perfectly happy with the table-mounted M12V with these modifications-accessories.) The PC 7518 is the best router I have ever used. I like its heft and feel. The handles are incredible--meaning they feel right and provide lots of control. Unfortunately, I put in a router table and have not removed it since for hand held routing. Shame. It's not a perfecttool. For instance, its speed fluctuates a bit. However, for router table applications, I doubt you'll find a better, stronger router for the price. By the way, I replaced a Makita M12V with this router. The M12V is now relegated to hand held work. (By the way, the Makita M12V makes a fine router-table router if you remove the springs, add the $80 Router Raizer, and use the bent arm wrench from Sommerfeld. I probably would have been perfectly happy with the table-mounted M12V with these modifications-accessories.)

|

Grizzly 1023S Table Saw

I really like this saw, and not just for the price. Okay, the price has a lot to do with why I like this saw. It's like I legally stole something. I understand why someone would buy a Powermatic or Delta. They're great saws. But I would never spend more for a clone, than the $800.00 you spend for the Grizzly 1023S. I really like this saw, and not just for the price. Okay, the price has a lot to do with why I like this saw. It's like I legally stole something. I understand why someone would buy a Powermatic or Delta. They're great saws. But I would never spend more for a clone, than the $800.00 you spend for the Grizzly 1023S.

|

Leigh Dovetail Jig

I have had the 1258R for many years. I originally liked it because it allowed me to do production dovetailing for little cost and effort. Of course now, there are a number similar jigs on the market. In fact, my Leigh gets less use now as I use a Porter Cable 7116 for half-blind dovetails and the Keller for through dovetails. However, it still has a place. When you want to space half-blind/through dovetails in a particular way, the Leigh is still the best. If you want one jig that does both half-blind dovetails and through dovetails, without having to store extra templates, again the Leigh is the best. I have had the 1258R for many years. I originally liked it because it allowed me to do production dovetailing for little cost and effort. Of course now, there are a number similar jigs on the market. In fact, my Leigh gets less use now as I use a Porter Cable 7116 for half-blind dovetails and the Keller for through dovetails. However, it still has a place. When you want to space half-blind/through dovetails in a particular way, the Leigh is still the best. If you want one jig that does both half-blind dovetails and through dovetails, without having to store extra templates, again the Leigh is the best.

|

|

|

Keller Dovetail Jig

I admit I am a newbie when it comes to the Keller. I have only had the Keller 1601 for a year, but it has become one of my favorite tools. The Keller does not require test cuts or elaborate setups and can be used to mill through dovetails on practically any angle/shape. You simply clamp it to your workpiece and go. If I want quick and easy dovetails, especially in my box construction, this is the jig I use. I also like the unlimited width capability of the jig. I was surprised to learn just how many pro shops use the Keller for their drawer and carcass construction. All in all it is a great tool--just wished I had used it sooner. I admit I am a newbie when it comes to the Keller. I have only had the Keller 1601 for a year, but it has become one of my favorite tools. The Keller does not require test cuts or elaborate setups and can be used to mill through dovetails on practically any angle/shape. You simply clamp it to your workpiece and go. If I want quick and easy dovetails, especially in my box construction, this is the jig I use. I also like the unlimited width capability of the jig. I was surprised to learn just how many pro shops use the Keller for their drawer and carcass construction. All in all it is a great tool--just wished I had used it sooner.

|

Shopsmith 510

After you stop laughing, let me explain. I bought this tool 10 years ago, knowing it would not be my primary saw or lathe. However, as a sanding and drilling system, it's pretty hard to beat. A lot of money for drilling and sanding? Yep. But when I need to sand a radius on a 3/4" x 24" x 48" panel, the price I paid does not come to mind. With that said, if you really think you have to own a Shopsmith, buy a used one. After you stop laughing, let me explain. I bought this tool 10 years ago, knowing it would not be my primary saw or lathe. However, as a sanding and drilling system, it's pretty hard to beat. A lot of money for drilling and sanding? Yep. But when I need to sand a radius on a 3/4" x 24" x 48" panel, the price I paid does not come to mind. With that said, if you really think you have to own a Shopsmith, buy a used one.

|

The following are a few tools I purchased that have been a disappointment.

|

|

Delta 14" Band Saw

I have offended just about everyone with this selection, but allow me to explain. I spent many hours on a band saw in a machine shop 20 years ago. It was a large beefy unit. Its guides handled a wide variety of blade widths. It had its own blade welder. I made my own blades from Olson blade stock. Also, since it had the blade welder, I could do inside cuts. Simply break the blade, feed it through the stock, and then weld it up.

I have offended just about everyone with this selection, but allow me to explain. I spent many hours on a band saw in a machine shop 20 years ago. It was a large beefy unit. Its guides handled a wide variety of blade widths. It had its own blade welder. I made my own blades from Olson blade stock. Also, since it had the blade welder, I could do inside cuts. Simply break the blade, feed it through the stock, and then weld it up.

When it came time to buy my own band saw in 1984, it appeared that the Delta was fairly common and well regarded so I bought one. I was quickly disappointed. The blade guides are poor, it is way underpowered, and where is the blade welder? I learned the grim reality of band saws. If you want a good all around band saw, you need to spend a lot of money. Back in 1984, I paid $450 for the Delta. You can buy one like it today for not much more. But to get a saw with decent guides, adequate power, etc., plan on spending two to three times that! Drat! Of course, the Delta is just a motor, set of guides, and a Mark Duginkse tune up away from being a good saw, but I am still disappointed!

|

Woodstock International Rebel Router Table

I wanted a "metal" router table to replace my shop-made table. I wanted a table that wouldn't sag under the weight of a 3-1/2 HP router. The Rebel doesn't sag, but it has some serious flaws:

I wanted a "metal" router table to replace my shop-made table. I wanted a table that wouldn't sag under the weight of a 3-1/2 HP router. The Rebel doesn't sag, but it has some serious flaws:

- Even after filing and smoothing out the top, it scratches workpieces.

- It leaves black marks on workpieces. This is not unusual for aluminum table tops.

- The fence stinks.

- Its height requires that you build some kind of cabinet, which I did. It's too tall for a workbench, too small to standalone.

- The table top is on the small side.

After all was said and done, I could have purchased a typical MDF unit for less and ended up with a better "system." I have fixed all of the above problems by building an auxiliary table and a new fence patterned after the Marc Sommerfeld fence. Click here to view the photos of my new setup.

|

Shopsmith 510

It is a poor table saw. The tables are too small, there is no way of placing a fixed measuring tape for measuring/making consistent rip cuts, the tilting tables don't work well when cutting long pieces, the tables flex under heavy pressure, etc. The lathe function is poor. It is too short and the tool rest is poorly designed. It is too light and instead of sliding in and out, it pivots. Trying to get it set just right is a royal pain. (Shopsmith offers an excellent replacement tool rest for just under $200.).

It is a poor table saw. The tables are too small, there is no way of placing a fixed measuring tape for measuring/making consistent rip cuts, the tilting tables don't work well when cutting long pieces, the tables flex under heavy pressure, etc. The lathe function is poor. It is too short and the tool rest is poorly designed. It is too light and instead of sliding in and out, it pivots. Trying to get it set just right is a royal pain. (Shopsmith offers an excellent replacement tool rest for just under $200.).

The rest of the package (drill press, disk sander, and horizontal bore) is pretty good. Of course the selling point of the Shopsmith is the little space it requires. Frankly, if you don't have enough space for a conventional table saw and drill press, you probably don't have enough space to do much woodworking. On the other hand, I have seen some pretty nice furniture created on Shopsmiths and I am in awe of anyone who can do it. To add injury to insult, after trying unsuccessfully to sell it, I had to pay for it "again" in a divorce settlement. My advice, don't buy a new Shopsmith unless you just have to have one.

|

Jointech introduced their saw train and router system for the Shopsmith 510. This might breathe new life into the old goat! The price is a bit high ($1100.00) but it looks really trick. Of course there is still a lot of fiddling around to do to raise blades, tilt the table, etc. You can check it out at Shopsmith Saw Train. Also, Incra has now released a Shopsmith fence and router kit. Like the Jointech, it should improve the table saw function 100%.

Jointech introduced their saw train and router system for the Shopsmith 510. This might breathe new life into the old goat! The price is a bit high ($1100.00) but it looks really trick. Of course there is still a lot of fiddling around to do to raise blades, tilt the table, etc. You can check it out at Shopsmith Saw Train. Also, Incra has now released a Shopsmith fence and router kit. Like the Jointech, it should improve the table saw function 100%.

|